Quick Mold Change Equipment: How It Works

ROEMHELD Quick Mold Change Systems

ROEMHELD manufactures highly engineered Quick Mold Change solutions that will help you speed up your mold change time, reduce inventories and manufacturing costs, and many other benefits that you can find below.

The systems are suited for small or large presses and a range of temperatures, and provide safe and reliable clamping to secure the mold during the production cycle. Clamp systems are available in magnetic, hydraulic, mechanical, or electro-mechanical. Mold shops want to achieve JIT (just-in-time) mold exchange, and that is where the experts at ROEMHELD can help.

Discover what type of Quick Mold Change is right for your injection molding machine.

Sign up to download our helpful guide.

Product Highlights

Click below!

M-TEC 240 advanced magnetic clamping techniques within the rubber and duroplatics processing industries. Max. working temperature: 240°C Learn More

|

M-TEC 120 being stable up to 120°C largely covers the whole temperature range that may occur in the thermoplastics processing industry. Learn More

|

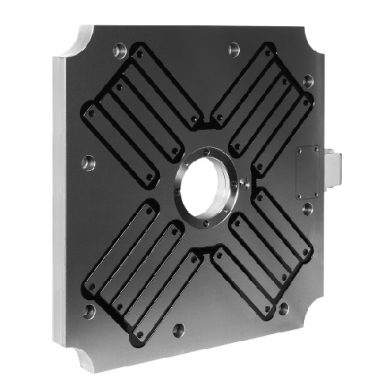

M-TECS 80 magnetic clamping systems are primarily used for automatic clamping of different dies on sheet metal forming presses and automatic punching machines. Learn More

|

used to lift the mold and provide a roller surface to easily roll the mold in and out during mold-changing. Learn More

|

safe and gentle transport of heavy molds. |

For clamping molds onto an injection mold machine. Provides additional safety with self-locking feature. |

Compact design, suitable where space is limited. |

manually placed on the clamping edge of the mold. |

Why Quick Mold Change?

Manufacturers are reducing inventory costs by running smaller batch sizes and making shorter production runs to survive in today’s competitive, worldwide market. One way to maximize press uptime in an environment like this is to implement faster, more effective mold changes. That’s where ROEMHELD, a leading Quick mold change system manufacturer, comes in.

What is Quick Mold Change?

A quick mold change means that the material for the next part is in place, automation is set-up and the mold is located and clamped in position. With the Quick-Mold change system, the mold is clamped in the same place, the same way, every time. Because of this, mold changes are accomplished in the shortest time possible.

When Quick Mold Change (QMC) is implemented, companies will enjoy the benefits of:

- Reduced Inventories, due to smaller quantities runs and more frequent changeovers.

- Increased Machine Capacity, by improving production and its product revenue.

- Improved Lead Times, due to quick changeovers.

- More Competitive, through just-in-time deliveries and better service to customers.

- Improved Quality of parts, due to repeatable positioning and clamping forces.

- Reduced Labor Costs, mold changes can often be done by the operator in a fraction of the previous time.

- Improved Safety, the molds are under control and roll smoothly in and out of the injection mold machine during the mold change, and with automated systems, if the mold is not clamped properly, the injection molding machine simply will not operate.

Discover what type of Quick Mold Change is right for your injection molding machine.

Sign up to download our helpful guide.

Online Catalog | Request a Catalog | Magnetics Information